07.07.2025

5 min

Batch Picking

Batch picking Warehouse – A Smarter Path to Efficiency

Imagine this: a picker in your warehouse walks five miles by noon—just to fulfill a handful of orders. Sound familiar? Now imagine if they could pick multiple orders in one go, cutting travel time in half and doubling their efficiency. That’s the power of batch picking—and with tools like Acumatica WMS, it becomes even easier to organize, track, and optimize every step.

In simple terms, batch picking in warehouse operations is a method where similar orders are grouped together and picked simultaneously. This order batch picking technique minimizes walking, speeds up fulfillment, and reduces strain on your team—all while maintaining accuracy. Acumatica WMS supports this process by grouping orders, guiding pickers through optimized routes, and helping your team stay efficient, even during peak times.

Whether you run a fast-paced e-commerce business or a complex B2B distribution center, the batch picking method can be a game-changer. In this post, we'll break down how it works, when to use it, and what tools you need to get started.

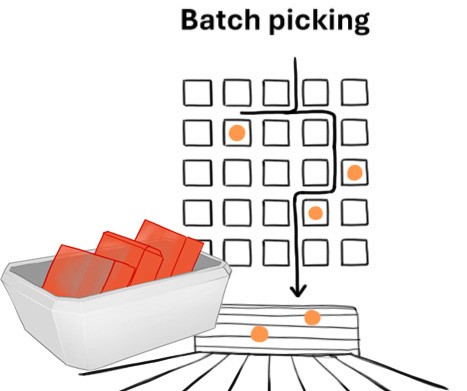

Think of batch picking as a smarter way to move through your warehouse. Instead of sending a picker out for one order at a time, you hand them a batch of orders, often with overlapping items, and let them fulfill multiple requests in a single trip.

This batch picking method reduces back-and-forth travel and leverages patterns in order data. For example, if five customers each ordered a popular item, a picker only needs to visit that location once to grab all five. It’s like turning a solo commute into a shared ride—fewer trips through the aisles, more orders completed per run.

Unlike discrete picking, where each order is picked from start to finish before the next begins, batch picking maximizes throughput by grouping similar items across multiple orders.

This approach is especially effective in high-volume settings like e-commerce, where speed and precision are non-negotiable.

How Batch Picking Works

Orders are grouped based on shared items or zones.

A picker receives a combined list, often via a mobile device or printed sheet.

Items are collected and later sorted by order at the packing station.

Case:

That’s what batch picking is—a practical, flexible strategy for warehouses looking to scale operations without burning out their team.

What are the batch picking advantages?

Why switch to batch picking? Because walking less and picking smarter means fulfilling more orders faster.

Batch picking doesn’t just save footsteps—it can seriously boost how your whole warehouse runs. It’s especially powerful when you’re dealing with hundreds or even thousands of orders every day.

Real-world example:

A mid-sized e-commerce warehouse was swamped trying to keep up with 600 orders a day during peak season. After switching to a batch picking approach with barcode scanners and mobile carts, their pickers got 40% more done, without hiring a single extra person.

Here's what you gain:

Increased efficiency: Pickers can fulfill 3–6 orders in the time it takes to do one.

Higher accuracy: Repetitive item picking leads to fewer errors.

Scalability: Grow your business without hiring more.

Reduced labor costs: More output per shift.

WMS compatibility: Modern systems like Acumatica WMS integrate smoothly with barcode scanners and mobile apps, making batch picking easy to manage, even as order volumes grow.

If your team is walking miles just to keep up with demand, batch picking could be the smartest move you make this year.

When and Where to Use Batch Picking

The batch picking strategy works best when:

Quick checklist:

1000+ daily orders with overlapping SKUs

Need to reduce walking time

Using barcode scanning

Looking to scale without scaling headcount

Example: A B2B food distributor cut picking time by 35% during peak season with batch picking—no new hires needed.

Tip: Already using or considering Acumatica WMS? You're in a great position—its batch picking functionality is built to handle this kind of volume with minimal setup.

What Does Batching Mean in Shipping?

In shipping, batching means picking items for several orders at once instead of one by one. It’s a smart way to speed up the process, especially when many orders share the same products.

Compared to order picking (also called discrete picking), where a picker completes one order before starting the next, batch picking saves time by reducing walking and repeating steps.

Unlike wave picking, which focuses on organizing picks by time or shipping deadlines, batch picking focuses on picking efficiency. The two can even be combined—using batch picking inside a scheduled wave—to get the best of both.

Tip: Batching helps you ship faster, especially when your warehouse handles a high volume of similar orders.

Tools and Equipment for Batch Picking

Batch Picking Carts & Trolleys

These mobile carts are not divided into bins or totes. Each cart holds items for all orders in the batch. Whether called batch picking carts or trolleys, they keep things organized and reduce sorting time later.

Mobile Devices & Scanners

Smartphones or handheld scanners show pickers what to grab and verify each item on the go. This boosts both speed and accuracy.

WMS and Batch Picking: A Realistic example of batch picking in Acumatica

Scenario: Automotive Spare Parts Distributor

15,000 SKUs

2,500 sqm warehouse

2,500 orders/day

Challenge: Long walking times, SKU complexity, pressure to ship faster.

Solution: Acumatica WMS with batch picking.

How It Works in Acumatica WMS

Acumatica’s WMS module is designed to support real-world warehouse workflows, including the use of batch picking carts, trolleys, and totes. It lets pickers work on several orders at the same time, with simple, clear instructions on where each item goes—so things stay organized and get done faster.

Step 1: Order Grouping

Sales orders with overlapping SKUs are automatically grouped into logical batches by the system. This reduces redundant travel and increases picking efficiency.

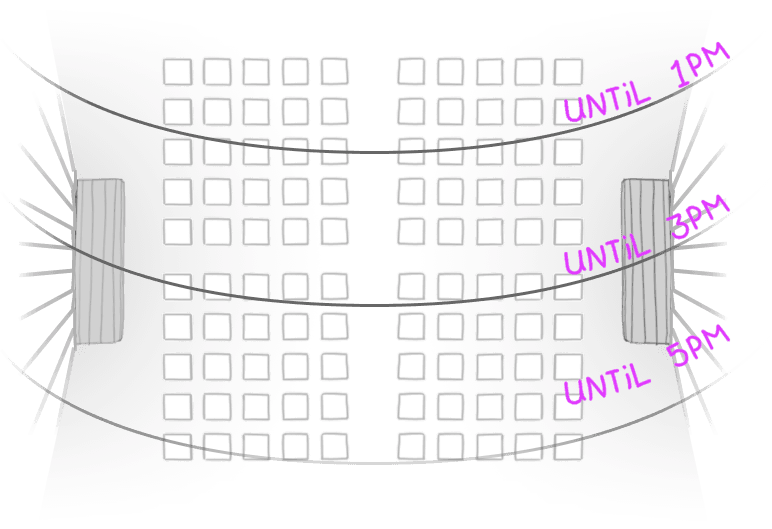

Step 2: Batch Picking Wave Creation

A warehouse manager launches a batch wave in Acumatica. The system assigns the batch to a picker and pushes it to their mobile device, along with an optimized route through the warehouse.

Step 3: Mobile Execution with Cart or Tote Support

The picker logs in via the Acumatica mobile app and receives a detailed picking list, organized by item and location.

As each item is scanned, the app displays which bin, tote, or cart slot it should go into.

This ensures each order stays properly separated, even when multiple orders are picked simultaneously.

The system supports labeling and tote tracking, making it easy to trace every item from pick to pack.

Whether you’re using multi-compartment picking carts or lightweight totes staged on trolleys, Acumatica WMS tracks every item and container.

Step 4: Staging and Sorting

Picked items arrive at a consolidation/staging zone. Since each tote or cart slot is already associated with a specific order, sorting is minimal, often just a confirmation scan.

Step 5: Packing and Shipping

Final verification and packing are completed in the shipping area. Acumatica generates labels, manages carrier selection, and provides end-to-end traceability—all within the same workflow.

33%

Zone Batch Picking: A Smarter Variation

When batch picking needs more speed and structure, go with zone batch.

Zone batch picking divides the warehouse into functional areas. Each picker stays in one zone and handles only items in that area. Orders are picked in parallel and merged later.

Example:

The automotive warehouse splits its layout into 4 zones:

Zone A: Filters & fluids

Zone B: Electronics

Zone C: Suspension

Zone D: Body parts

The WMS pushes the batch out to each zone, and every picker grabs their items and drops them off at a central spot to be combined later.

Key Benefits:

Orders get picked faster because everyone works at the same time

Less traffic in the aisles

Pickers get really good at their own sections

Easy to grow the team or warehouse as you get more orders

Conclusion

So, what does batching mean in shipping? It’s a flexible, efficiency-focused process that cuts down the time between receiving an order and getting it on a truck. It’s not a replacement for all warehouse methods, but when combined with smart WMS tools and good process design, batch picking is a key strategy for fast, accurate, and scalable shipping.

If your warehouse team is constantly under pressure to pick faster and ship sooner, it might be time to rethink your picking strategy.

Batch picking offers a simple but powerful upgrade—grouping orders to reduce travel, speed up fulfillment, and boost productivity. And when combined with tools like batch picking carts, mobile scanners, and a flexible WMS system like Acumatica, the results speak for themselves.

Whether you’re managing a growing e-commerce shop or a high-SKU distribution center, adopting a batch picking method—or even advanced setups like zone batch picking—can help you scale without burning out your team.

Fewer steps

Faster orders

Smarter workflows